• Large-scale production of secondary metabolites from medicinal plants using bioreactor culture technology |

• Mass propagation of horticultural plant through plant tissue culture and bioreactor culture techniques |

• Production of high quality transplants using hydroponic culture techniques |

• Morphological, physiological, and biochemical responses of in vitro produced plants during acclimatization |

• Flowering physiology of ornamental plants |

• Physiology of Plant Secondary Metabolism |

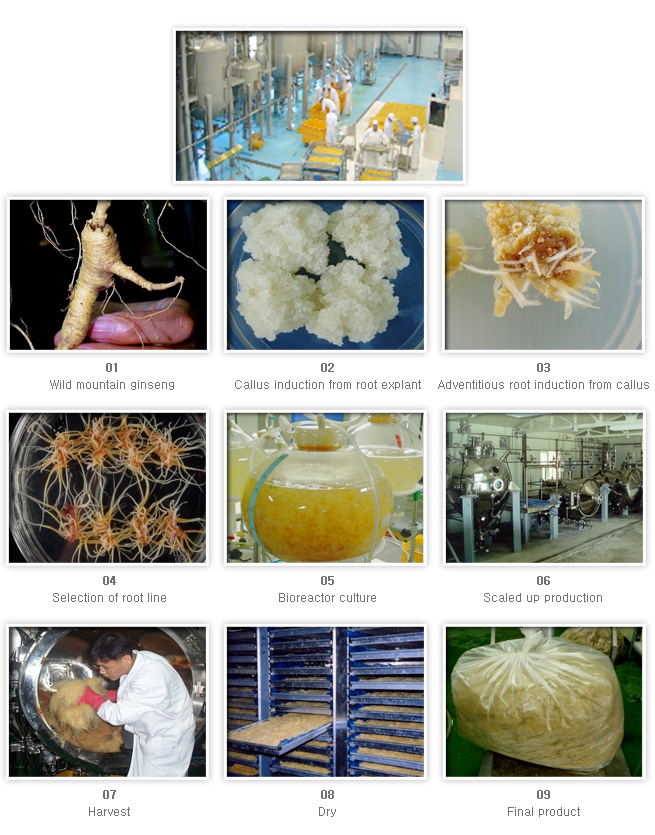

1. Selection of high-valued plant materials and establishment of tissue culture system. |

2. Large-scale cultures of cell lines containing useful bioactive compounds; Screening and isolation of new functional materials through collaborations with pharmaceutical and medical research teams; |

3. Establishment of pilot-scale bioreactor system: Design and culturing process in pilot-scale bioreactors through optimizations of bioreactor type, sparger, culturing medium; system automation. |

4. Research on secondary metabolism: Elicitation for maximizing bioactive compounds; Determination of safety, toxicity and efficacy of the products by joint studies with certified national institutes to develop functional food and alternative medicine. |

1. Planttissueculture |

Planttissueculturetechniquesofferanintegratedapproachfortheproductionofstandardizequality phytopharmaceuticalthroughmassproductionofconsistentplantmaterialforphysiologica lcharacterizationandanalysisofactiveingredients. Inourlab,micropropagationsystemshavebeensuccessfullydevelopedforseveralmedicinalspecies such as Panaxginseng, Echinacea, Eleutherococcussessiliflorus ,Gymnemaetal. |

2. Secondary metabolism |

The concentration of commercially important secondary metabolites demonstrated the utility of tissue culture approaches. In our lab, a ‘two-stage culture’ system is being applied for biomass and compound production: Culture conditions are regulated to optimal levels for biomass increase, followed by enhancing secondary metabolite accumulation through various elicitations. |

3. Discovery of new compounds |

Novel active compounds and derivatives of bioreactor-produced plant materials have been identified by chemical profiling of secondary metabolites using HPLC/MS. Analytical database (25,000 natural compounds) confirmed 25-30% of the materials as new chemical profiles(BioPlanta, Germany). In the final product of tissue cultured mountain ginseng root, Mormordicoside C, 15-Malonyl and 1,3,5-trihydroxy-2-pre Aloesaponarin have been detected, which were not found in field-cultivated ginseng. The development of these in vitro techniques can provide a ready-source for biochemical characterization and identification of active constituents. |

4. Large-scale production in bioreactors |

Biomass production significantly increases with increasing bioreactor volume but the culture conditions (both chemical and physical factors) should be adjusted to culture species, explant type and cultural objectives. We have obtained more than 150-fold or more in a 10-ton bioreactor, producing 1000-1300 kg fresh weight of ginseng adventitious root in a 10-ton bioreactor with approximately 10-12% root dry weight. |

Mass production and commercialization of cultured mountain gibseong and useful medicinal plants using state-of-the-art bioreactor technology |

With creative and extensive R&D on biotechnology, succeeded in producing the essence of high value added medicinal plants identical with that of the natural cultivated plants using the state-of-the-art technology of cell culture. |

Succeeded in using advance culture technology for elicitation of special ingredients in medicinal plantssuch as ginsenoside, polysaccharides, antioxidant related enzyme activities et al. Developed new method to add medicinally effective ingredients in cultured medicinal plants, which are not contained in field grown plants. |